Our Equipment Reconditioning Process: Quality You Can Trust

When it comes to maintaining a clean facility, dependable floor care equipment is essential. However, it’s no secret that new floor cleaning machines can be expensive and buying used machines “as-is” can lead to unexpected costly repairs. But don’t worry, you don’t have to break the bank to get high-quality equipment. Our reconditioned equipment can deliver the same reliable performance as a new machine at just 50-60% of the cost.

We’re committed to providing our partners with a more cost-effective option that doesn’t compromise on quality or reliability. Continue reading to learn about our expert reconditioning process.

Step-by-Step Reconditioning Process

1. Comprehensive Inspection

We begin the reconditioning process with a full comprehensive inspection and test run of the machine. Our in-house trained technicians assess the overall condition of the machine and identify any components that need to be repaired or replaced.

2. Deep Cleaning and Cosmetic Restoration

Every machine is power washed inside and out to remove any dirt, grime, or residue from previous use. Then, we touch up the exterior of the machine with paint to cover noticeable blemishes for a refreshed, professional appearance.

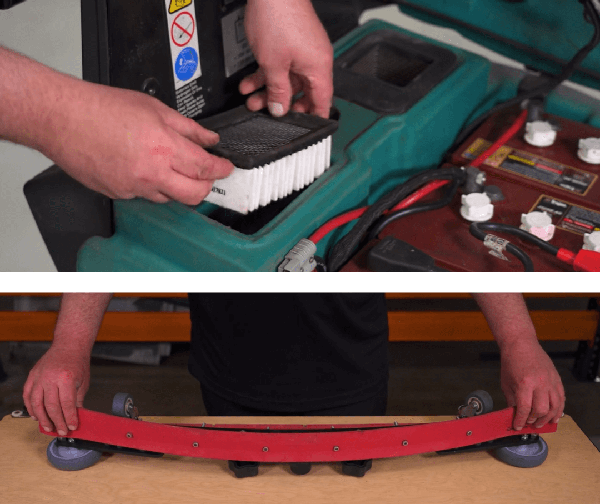

3. Replacement of Wearable Components

As part of our standard procedure, we replace all critical wearable parts, including:

- Squeegee blades

- Hoses

- Filters

- Deck skirts/curtains

- Casters

- Batteries and cables

- Any other parts necessary to restore full functionality

This ensures that your machine not only looks good, but reliably performs like a new machine.

4. Functional Testing

Every machine undergoes a final operational test run before it leaves our facility. We confirm that all systems are functioning properly and meet our performance standards so that the machine is ready to use when it arrives.

Why Buy Reconditioned Equipment from Triad Service Center?

On-Site Delivery and Training

If you’re located within our service region, we will deliver your reconditioned equipment directly to your site. Plus, we’ll send one of our experienced technicians to train your staff on:

- How to operate the machine (especially if it’s a new model for your team)

- How to perform daily maintenance to keep it running smoothly

Warranty Coverage

Because we stand behind the quality of our work, we offer the most comprehensive warranty coverage for refurbished equipment in the industry. Every reconditioned machine comes standard with a 90-day warranty coverage on major components and any associated repair labor, along with a 30-day warranty covering repair visit travel fees.

- 90-day warranty on major components & associated labor

- 30-day warranty on travel fees

Please note: Warranty coverage only applies to part malfunctions that were not caused by damage or neglect.

Fleet Rebuild Options

Managing a fleet of machines? We offer discounted, flat-rate pricing for reconditioning multiple machines. We’ll work with you to tailor your rebuild plan to meet your needs and budget.

Contact Triad for Reconditioned Floor Cleaning Solutions

Reconditioned floor cleaning equipment is a smart, affordable, and sustainable choice—and our process guarantees you get the reliable, high-quality performance you need. Whether you're replacing a retired machine or looking to upgrade your facility’s cleaning regimen, we’re here to help you get the most out of your investment.

For help finding the right machine for your facility or to request a quote for fleet rebuilds, contact us today:

Call us: (888) 834-9948

Click here to view our large inventory of reconditioned equipment.

©